Our Facility

Where precision engineering meets modern manufacturing.

Modern Manufacturing Setup

Plast Mould India operates a well-equipped production facility designed for high-quality and consistent injection Moulding. Our workspace, machinery, and systems are optimized to support fast turnaround, precision output, and smooth workflow from tool development to final production.

Injection Moulding Unit

Our Moulding unit features multiple tonnage machines capable of handling a wide range of components — from small precision parts to mid-size functional products.

- Multi-tonnage injection Moulding machines

- Capable of ABS, PP, PC, Nylon, POM & engineering plastics

- Stable, repeatable production cycles

- Skilled operators for consistent part quality

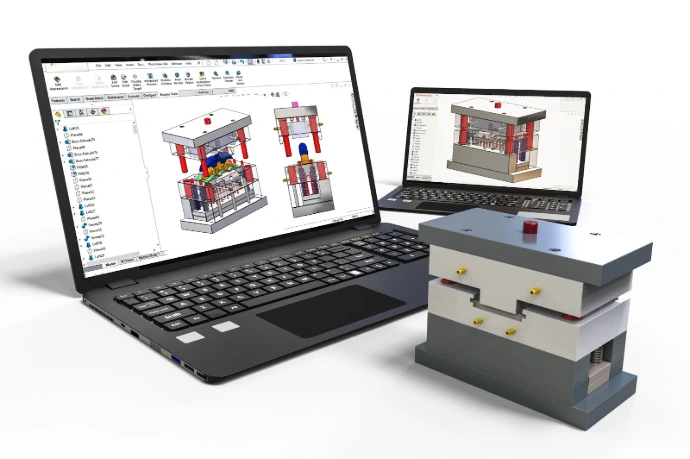

Tool Room

Our in-house tool room supports complete mould development, repair and maintenance. Equipped with CNC, EDM and finishing stations, our team ensures every mould remains production-ready at all times.

- New mould development

- CNC machining & EDM operations

- Preventive maintenance for extended mould life

- Quick modification & repair capability

Quality Control Lab

Every batch undergoes strict inspection to ensure dimensional accuracy and material performance. Our QC workflows maintain precision, stability, and reliability across every product.

- Vernier, micrometer, height gauge measurements

- Visual & dimensional inspection

- Material quality verification

- In-process quality checks at every stage

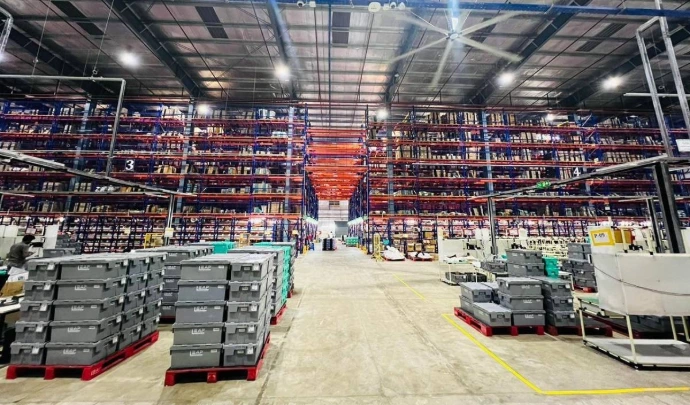

Materials & Storage

Raw materials are stored in a controlled and organized environment to maintain polymer quality and traceability.

- Dedicated raw material storage racks

- Moisture-controlled environment

- Labeled materials for easy identification

- FIFO-based material handling system

Production Workflow

Our streamlined production sequence ensures efficiency, precision, and fast delivery.

1

Material Preparation

2

Mould Setup & Machine Calibration

3

Trial Run & Parameter Optimization

4

Batch Production

5

In-Process & Final Inspection

6

Safe Packing & Dispatch

Safety & Compliance

A safe workplace is a productive workplace. Our facility follows structured safety guidelines and industry best practices.

- Trained operators & supervisors

- Machine safety guards & SOPs

- Organized, clean working environment

- Compliance with standard manufacturing norms

Facility at a Glance

20+ Machines

Injection Moulding setup

1200+ Sq. Ft.

Tool room infrastructure

5M+ Parts

Delivered reliably across industries

24×7 Production

Capability with shift operations

Facility Gallery

A glimpse into our manufacturing environment and operations.

Visit Our Facility

We welcome customers to walk through our setup and understand our production capabilities in person.

For appointments or site visits, contact our team.

info@plastmouldindustries.co.in

Phone

+91 9899556769, 9811676911

Office

Unit-2, Plot no - 2120, Phase-II, Rai Industrial

Estate (HSIIDC), Sonipat, Haryana-131029, India